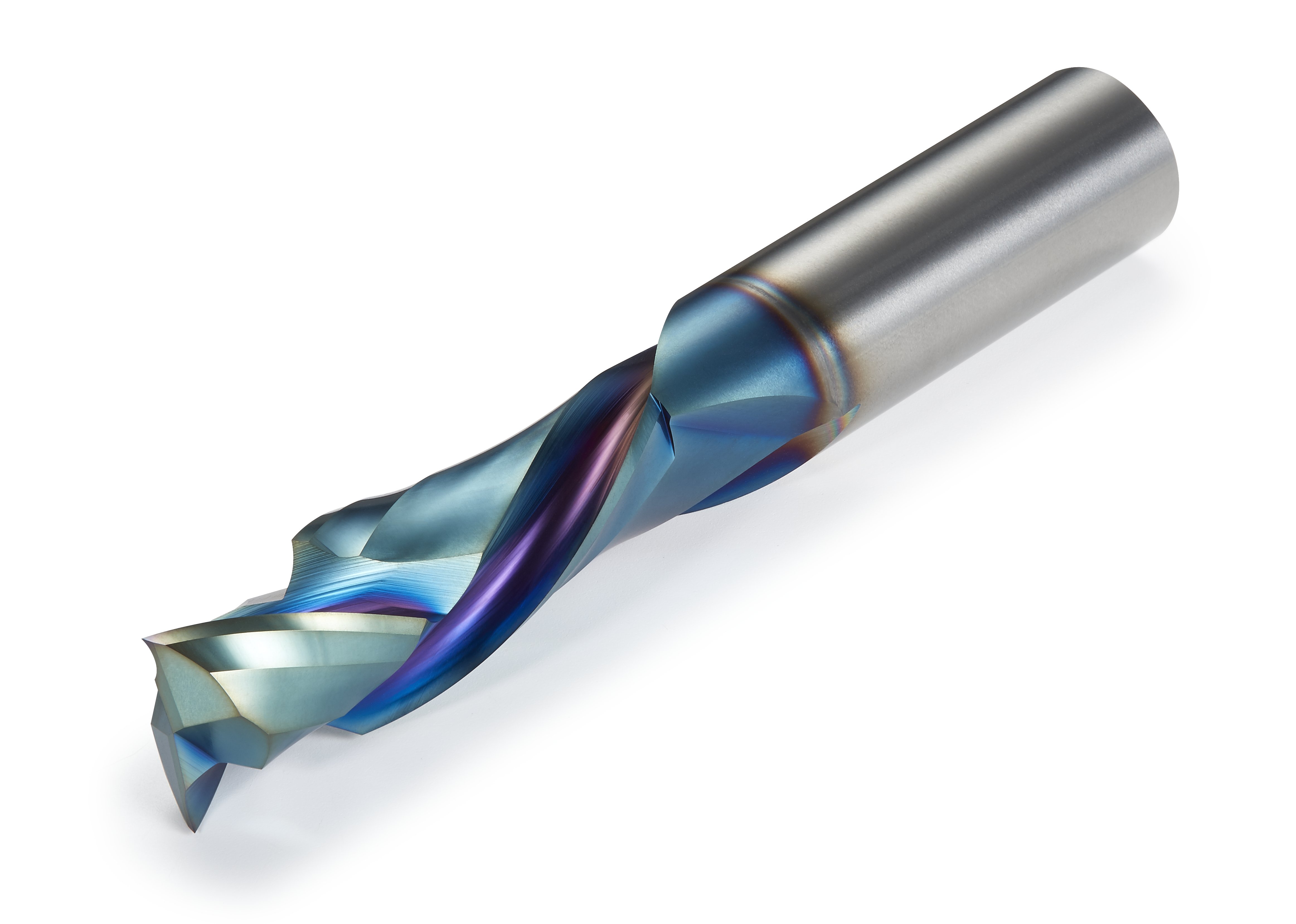

Tool materials utilised in the manufacture of router bits in the industrial market place involve high-speed steel, carbide tipped....

Cutting tool geometry influences many factors including the type of chip produced, the flow of the chip....

Flank Wear - Clearance or relief side of the edge is wearing and rubbing. This is how most router bits....

To understand the concept of speeds and feeds, it is necessary to visualise what occurs at the cutting edge of the tool...

For time studies the below and true average chip loads use the following information....

Many users select tools without regard to the importance of adequately holding them in the colleting system....

Many times CNC routers are set up almost perfectly with the right tools, elaborate vacuum systems, and somehow....

In most cases, conventional cutting provides the best edge provided the right tool geometry to cut a specific material....

Tool selection involves and evaluation of the circumstances regarding the application and asking questions or....

Here you will find a value analysis for competitors against LMT Onsrud tooling offering a breakdown of....

Wood, unlike plastic and aluminium, has a wide range of chipload. The difference is varied because of the goal....

Not so many years ago, the machining of plastics was more of an art than a science. The typical sheet fabricator....

There are many types of aluminium's in two basic conditions. The conditions have more effect on the routing cuts....

The tool can be the weakest part of the routing system. However, almost 80% of breakage problems can be....

Sometimes there are terms thrown around that you have never heard of. Take a look below to see if you....